Occupational exposures that can give rise to occupational disease represent the single most significant health & safety risk in the mining industry globally. As part of our work towards Teck’s goal of eliminating occupational disease, in 2020 we completed the Nanozen pilot project, which uses an innovative combination of on-the-ground data and video technology to help us better understand potentially harmful dust exposures at a task level. The goal is to understand task level exposures so we can laser focus critical control strategies to reduce employee exposures.

This large scale pilot project, which included our Greenhills, Fording River, and Highland Valley Copper Operations, was funded by Teck’s Ideas at Work program. The pilot program leverages the power of advanced analytics to collect real-time exposure data for job roles including pit crews, mechanics, and equipment operators.

Health and Safety Benefits of Real-Time Monitoring Technology

Exposure to dust at mine sites is a potential health and safety hazard, leading to respiratory diseases if proper precautions are not taken. For years it has been industry standard to rely on daily sampling methods, averaged over the length of a shift, to determine dust exposure. These sampling methods provide one value indicating an employee’s overall dust exposure for a shift.

By making use of Nanozen’s real-time monitoring technology, we have been able to greatly improve the collection of information about dust levels during a work shift. Instead of a single value for an entire shift, we can now monitor live, accurate information on the concentration of dust exposures. This has enabled us to better understand how and when these exposures occur, and to target controls that reduce exposures from higher-risk activities.

Research in Action

In 2020, the Nanozen pilot project was initiated at sites to deploy this innovative technology into a wide range of roles including field and shop mechanics, pit utility and cable crews, bulldozer and grinding operators, and laboratory workers involved in sample processing. Going above and beyond a simple analysis of the data, Teck’s Occupational Health and Hygiene team leveraged the power of advanced analytics, diving deep into the data to find meaningful results and actionable changes. This increased volume of research data has helped us to pinpoint the specific activities and times where dust exposures occur and prioritize approaches to mitigate them.

“Applying analytics to real-time particulate monitoring helps us determine exactly which activities lead to high dust exposures, allowing us to recommend and implement targeted controls to improve employee health and safety”, said Dan Sarkany, Lead, Occupational Hygiene at Teck Coal.

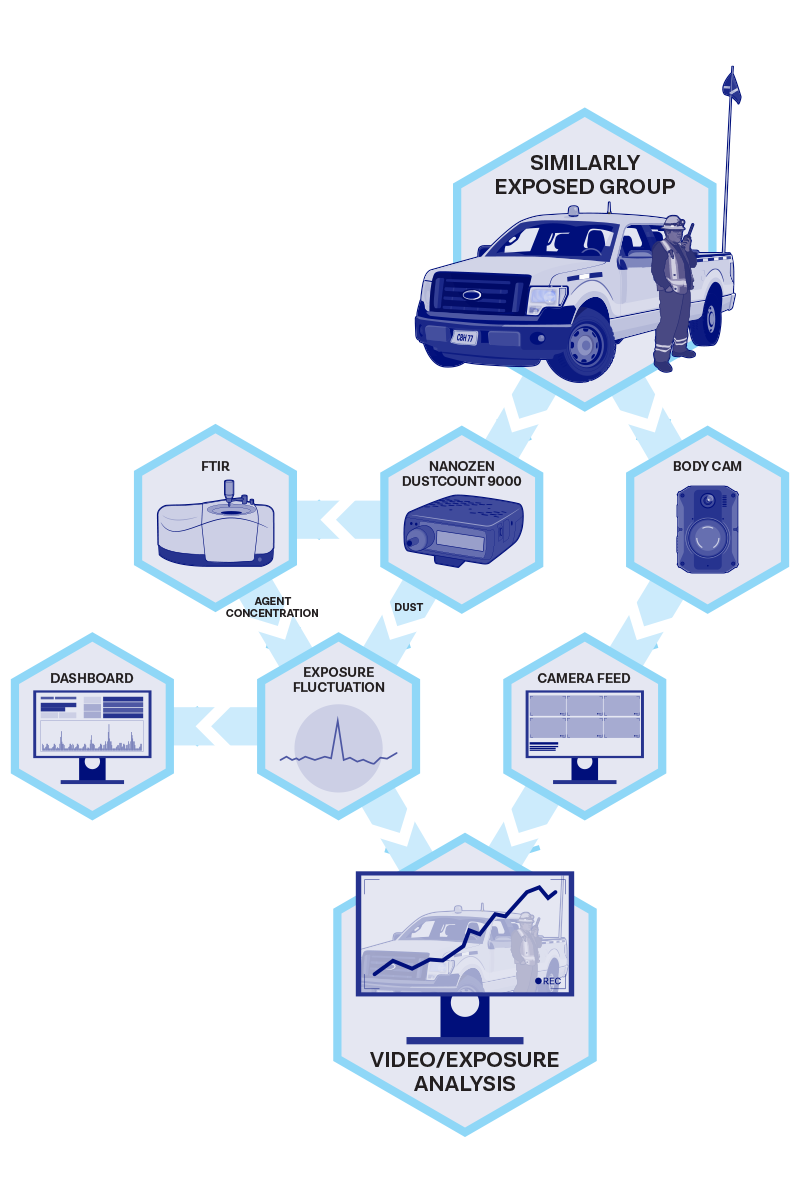

Graphic: An overview of the instruments and tools deployed for the Nanozen pilot project.

This pilot project coupled Nanozen real-time dust monitoring technology with on-site video recordings and video analysts trained to recognize job activities. The footage collected maintained confidentiality and privacy by blurring faces and skin tone, and no audio was recorded. We had the full support of our workforce to undertake this important work and we are very thankful for all the employees that participated so positively.

“This project represents a leading health and safety initiative in the mining industry and other industries with dust exposures”, said Corrine Balcaen, Director, Occupational Health & Hygiene.

Real-time dust monitoring, and the targeted controls developed as a result of the learnings, will continue to be implemented throughout our operations going forward. This technology serves a key role in improving exposure controls and working towards Teck’s goal of eliminating occupational disease.

Read more about our approach to Health and Safety on our website.